Business

Waymo Engineers Launch Startup to Automate Excavators for Construction

San Francisco, CA — A team of engineers from Waymo is venturing into a new market by automating construction equipment. In 2024, Boris Sofman, a prominent Waymo engineer who previously focused on truck automation, partnered with former Waymo colleagues Ajay Gummalla and Kevin Peterson, as well as engineer Tom Eliaz, to establish Bedrock Robotics.

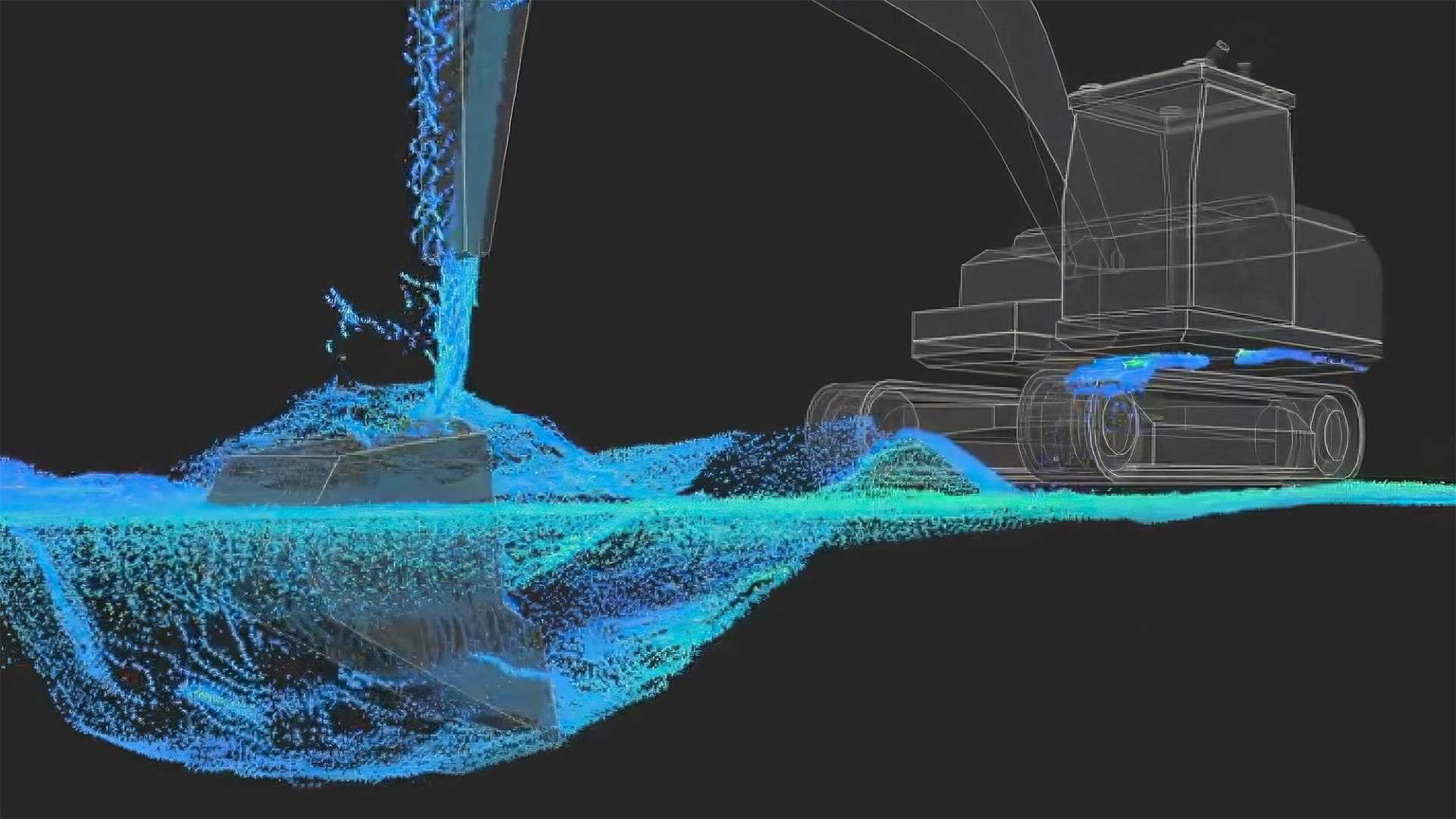

The startup aims to modify existing excavators rather than create new machinery. Using cameras, lidar, computers, and AI software, Bedrock plans to enable excavators to operate continuously, even in extreme heat, addressing the limitations of human workers who need breaks.

Bedrock Robotics has emerged from stealth mode with $80 million in funding and aims to begin commercial operations by 2026. “It’s another one of those transportation-style spaces that is due for a wave of what’s happening in transportation,” Sofman told Forbes.

The U.S. construction industry faces a challenging landscape characterized by high demand for new projects and escalating materials costs fueled by tariffs. “You have an astronomical macroeconomic tail and a need to re-industrialize the U.S.,” Sofman explained.

The recent passage of Biden’s Bipartisan Infrastructure Law, combined with rising demand in construction, is projected to increase U.S. excavator contract revenue to $145 billion this year, a 2.5% rise, according to an IBISWorld report. Bedrock is working towards securing additional funding within a year.

Testing of autonomous excavators is currently underway at sites in Arizona, Texas, and Arkansas, with plans to expand testing to customer worksites soon. “We expect to get the first operator-out form in 2026,” Sofman stated.

Former Waymo CEO John Krafcik praised the founding team for their technical capacity and vision, highlighting the potential for change in the construction sector. Unlike Waymo’s driverless cars, Bedrock’s autonomous machines face fewer regulatory challenges on private construction sites.

With construction labor shortages and a tightening labor pool, Bedrock’s technology could help firms manage costs better and expedite project completion. “It will allow human crews to focus on more complex tasks,” said Eric Cylwik at Sundt Construction, a firm collaborating with Bedrock.

Cylwik added that Bedrock’s modifications could significantly lower costs and increase efficiency, as robotic excavators can handle repetitive tasks overnight while humans engage in installations. Recent research shows there’s an ongoing shortage of laborers, especially as many are nearing retirement.

Bedrock plans to keep its pricing for upfitting excavators competitive, while leveraging existing fleets instead of building new machines from scratch. This provides construction companies with a cost-effective means of incorporating advanced technology into their operations.

The partnership and interest from construction firms suggest that Bedrock’s strategy could enhance productivity within the industry in a time of significant economic and structural challenges.