Business

The North Face Collaborates with Scientists to Develop PHA Fiber for Sustainable Outdoor Apparel

The National Renewable Energy Laboratory (NREL) is partnering with the Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE) consortium in an innovative project to address microplastic pollution in the outdoor apparel industry. This collaboration aims to develop biodegradable PHA fibers to replace traditional petroleum-derived polyester clothing, which is a major contributor to environmental microplastic contamination.

PHA, short for polyhydroxyalkanoates, are biodegradable and biobased materials with properties that make them suitable for textile production. The team of scientists from NREL and Colorado State University has successfully created a range of PHA polymers that mimic the characteristics of polyester but are more environmentally friendly.

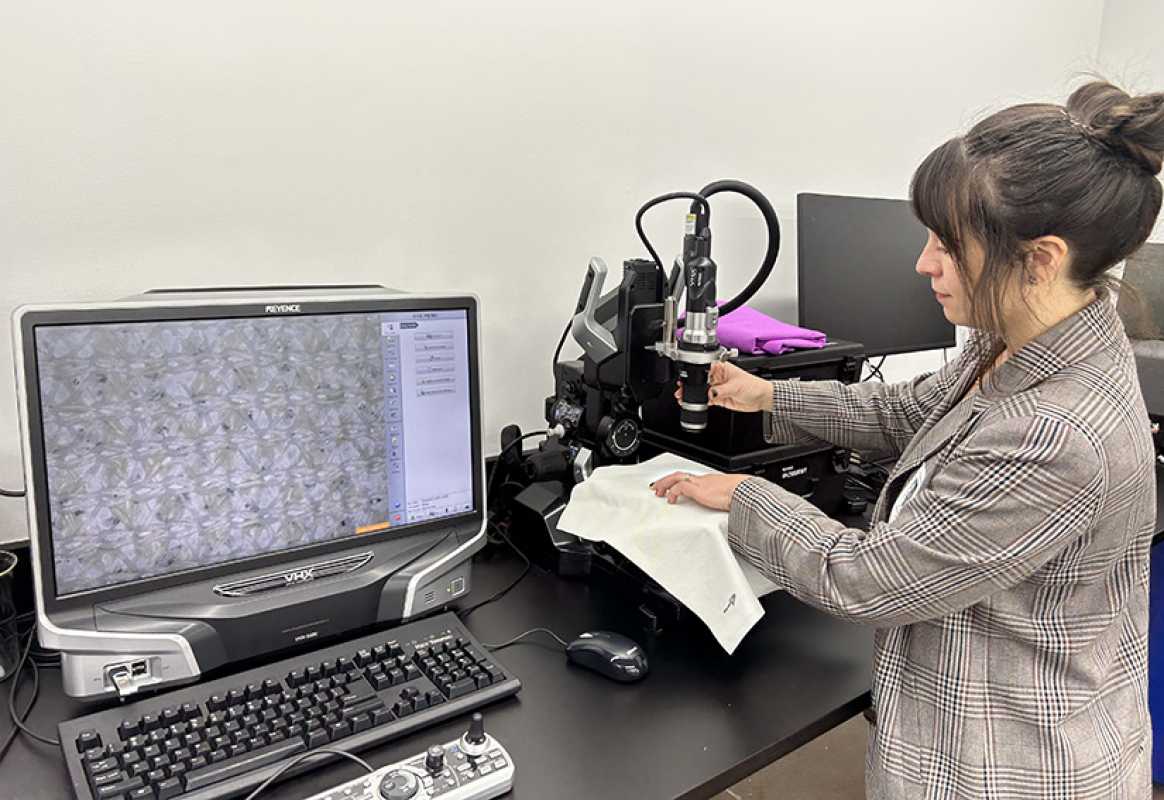

The North Face, a prominent outdoor apparel company, has joined forces with BOTTLE to test and evaluate the newly developed PHA fibers for potential use in their product lines. Over the next year, the project will scale up production to produce a significant amount of PHA fiber for testing.

Previously, producing textiles from PHA was a challenge due to limitations in controlling the material’s properties. However, advances in synthetic routes using biobased building blocks have enabled scientists to tailor PHA’s chemical structure to achieve desired attributes such as melt-processability and biodegradability.

The redesigned PHA structure developed by the BOTTLE team enhances the material’s thermal stability and recyclability. With these improvements, PHA can be easily deconstructed into its building-block monomers for reuse in producing high-quality plastics.

The sustainability of PHA textiles is a key focus of the collaboration, with research underway to assess the energy and carbon footprint of the production process. Additionally, the project will investigate the shedding and biodegradation rates of PHA fibers in various environmental conditions to compare them to conventional polyester.

Carol Shu, senior manager for global sustainability at The North Face, expressed the company’s commitment to materials innovation and sustainability. The partnership with BOTTLE aligns with The North Face’s goal of creating high-performing products with minimal environmental impact and supporting product circularity.

Following the initial testing phase, The North Face plans to involve its suppliers in evaluating prototype PHA fibers for potential inclusion in a more sustainable product line. The ultimate aim is to offer consumers outdoor apparel that not only performs well but also minimizes microplastic pollution in the environment.